Cooling Towers Components Working Principles And Lifespan A

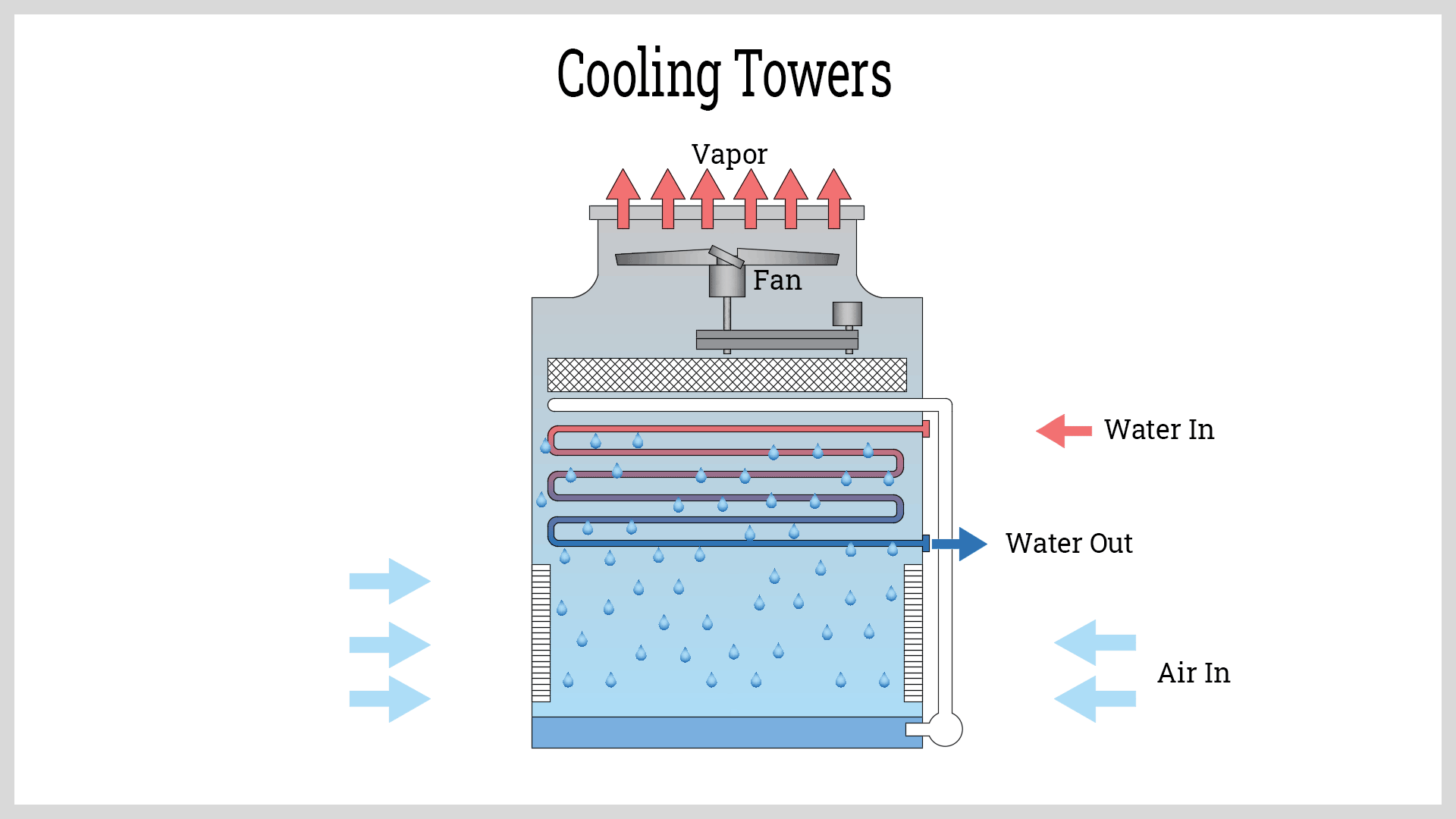

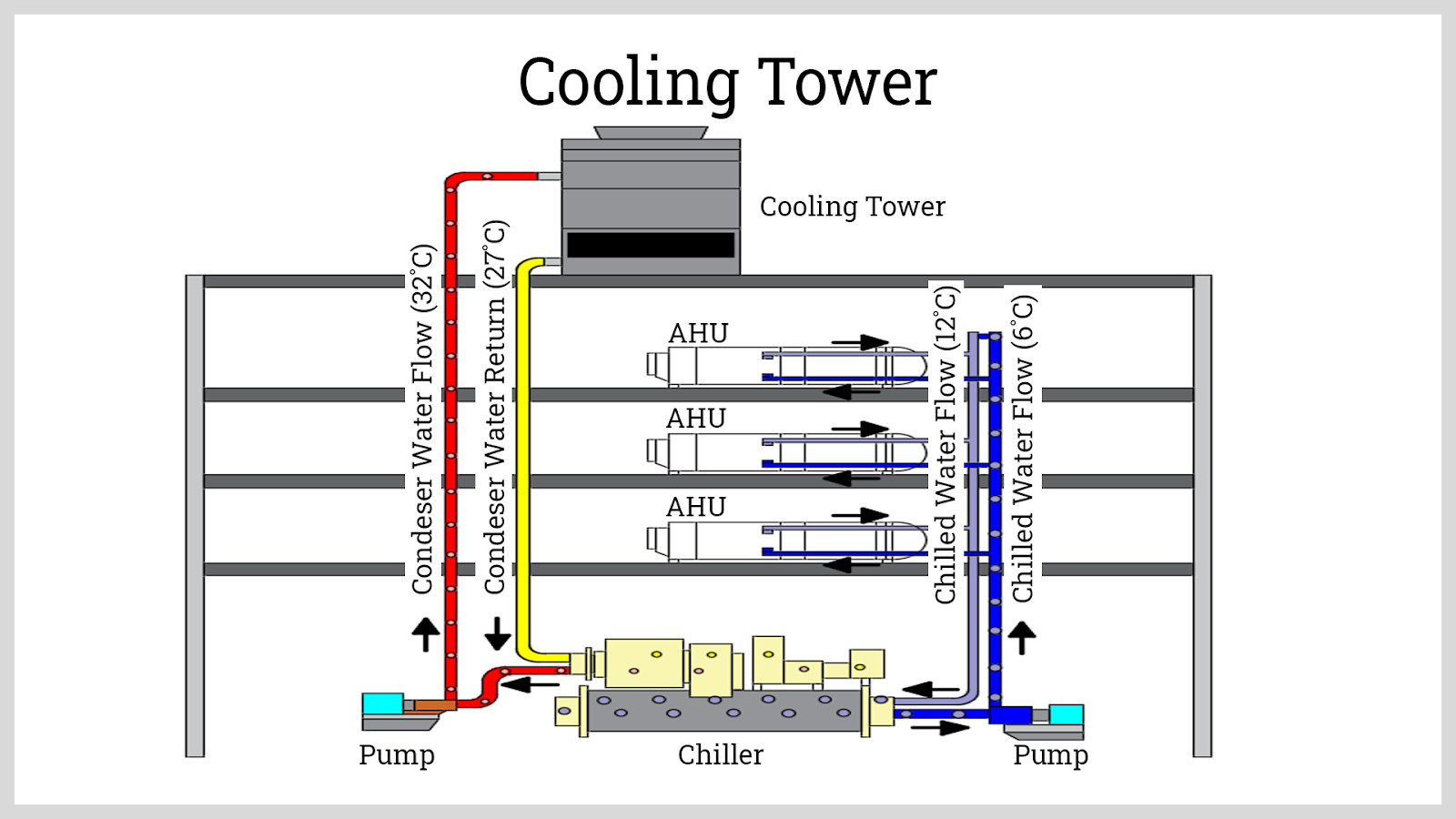

Cooling Towers Components Working Principles And Lifespan A The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the. Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. during this process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower.

Cooling Towers Components Working Principles And Lifespan A Evaporative cooling towers are able to best realise the water air heat exchange process: evaporation is forced through the use of simple, effective components which normally require minimum maintenance. to better understand how heat dissipation occurs, two concepts need to be introduced. sensible heat. The cooling tower uses the principles of evaporation and airflow to remove heat from the water, allowing it to be recycled back to the condenser for continuous cooling. the comprehensive working principles of a cooling tower. the cooling tower system operates based on the following working principles: hot water circulation. the cooling tower. A cooling tower, although simple looking, is made up of 38 different components and systems, as detailed in the list below, to ensure it operates correctly and at optimum efficiency. steelwork base. cooling tower casing. access door. portable crane. name plates. external access maintenance. platforms. external ladder systems. external. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging.

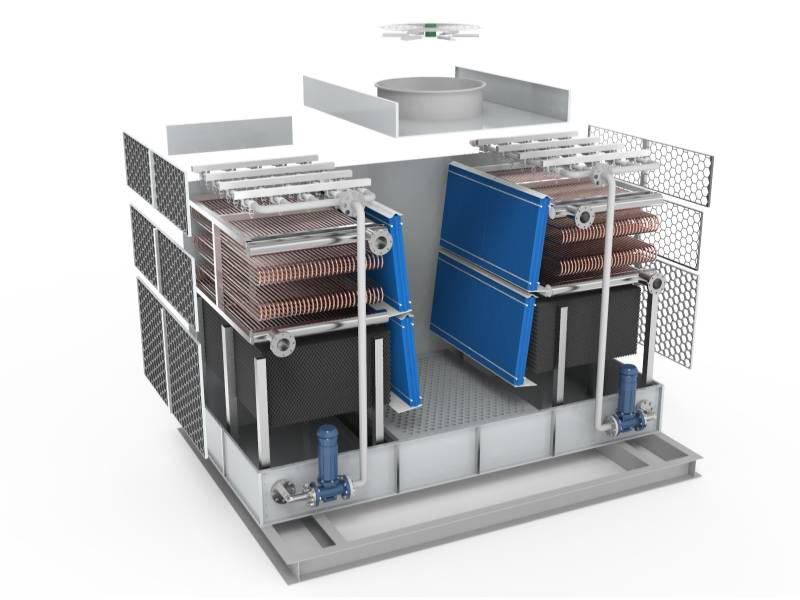

Cooling Towers Components Working Principles And Lifespan A A cooling tower, although simple looking, is made up of 38 different components and systems, as detailed in the list below, to ensure it operates correctly and at optimum efficiency. steelwork base. cooling tower casing. access door. portable crane. name plates. external access maintenance. platforms. external ladder systems. external. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. A typical evaporative, forced draft open loop cooling tower rejecting heat from the condenser water loop of an industrial chiller unit natural draft wet cooling hyperboloid towers at didcot power station (uk) forced draft wet cooling towers (height: 34 meters) and natural draft wet cooling tower (height: 122 meters) in westphalia, germany natural draft wet cooling tower in dresden (germany). The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser.

Comments are closed.